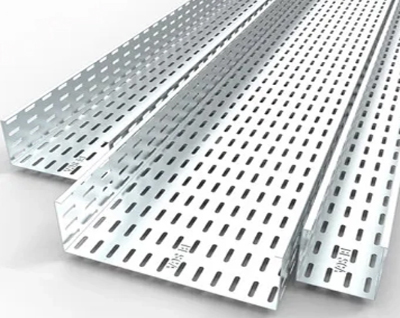

A common type of cable tray that has holes in the bottom sheet and side rails and is used to lay power and signal cables is called a perforated cable tray. Strong construction enables perforated cable trays to support several cables of various types. These have rounded edges that guard against scuffing the wires. The cable trays can tolerate short circuits because of their durability.

Electricity is distributed in department stores, airports, hospitals, and gyms via perforated cable trays. Flexible and simple to install, perforated cable trays are. The overall upkeep is also minimal.

The cables that are utilised to hold the cable wires for both indoor and outdoor use are effectively ventilated by perforated cable trays.

| S.No | Material Finished | Specifications | Recommended |

|---|---|---|---|

| 1 | Pre-Galvanized | As Per Specifications | Indoor |

| 2 | Hot - Dip Galvanized | As Per IS 4759,2629, 2633 | Indoor & Outdoor |

| 3 | Powder Coated | As Per Specifications | Indoor |

| 4 | Stainless Steel | As Per Specifications 304, 316. | Indoor & Outdoor |

| 5 | Aluminum | As Per Specifications | Indoor |

Note:

- R stands for the market's usual sizes.

- NR translates into producing items that are not standard size to meet customer demand.

- NA It denotes a product that is either unavailable or unlikely to be used in the market, yet we nonetheless provide it based on consumer demand.

| Width of Cable Trays | ||||||||||||||

| S.NO | Thickness | Depth | 50 | 100 | 150 | 200 | 300 | 450 | 500 | 600 | 750 | 900 | 1000 | 1200 |

| 1 | 1.6 mm | 25 MM | R | R | R | NR | R | NR | NR | NR | NR | NR | NR | NR |

| 2 mm | R | R | R | NR | NR | NR | NR | NR | NR | NR | NR | NR | ||

| 2.5 mm | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | ||

| 3 mm | Based on Customer Requirement | |||||||||||||

| 2 | 1.6 mm | 40 MM | NR | NR | NR | NR | NR | NR | NA | NA | NR | NR | NR | NR |

| 2 mm | NR | NR | R | R | R | R | NR | R | NR | NR | NR | NR | ||

| 2.5 mm | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | ||

| 3 mm | Based on Customer Requirement | |||||||||||||

| 3 | 1.6 mm | 50 mm | NR | NR | R | NR | R | NR | NA | NR | NR | NR | NR | NR |

| 2 mm | NR | NR | R | NR | R | R | NA | R | R | NR | NR | NR | ||

| 2.5 mm | NR | NR | NR | NR | NR | NR | NA | R | R | NR | NR | NR | ||

| 3 mm | Based on Customer Requirement | |||||||||||||

| 4 | 1.6 mm | 75 mm | NR | NR | NR | NR | NR | NR | NA | NR | NR | NR | NR | NR |

| 2 mm | NR | NR | NR | NR | R | R | NA | R | NR | NR | NR | NR | ||

| 2.5 mm | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | ||

| 3 mm | Based on Customer Requirement | |||||||||||||

| 5 | 1.6 mm | 100 mm | NR | NR | NR | NR | NR | NR | NA | NR | NR | NR | NR | NR |

| 2 mm | NR | R | R | NR | R | R | NA | R | NR | NR | NR | NR | ||

| 2.5 mm | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | NR | ||

| 3 mm | Based on Customer Requirement | |||||||||||||

- Easily maintained

- Creates seamless designs.

- The trays are dependable and long-lasting.

- Loaded specifications are available.

- Perfect for dealing with strong pressure.

Utilizing cutting-edge technology, which is used specifically to meet the clients' specialised needs, the product is manufactured. Depending on the various sectors, such as cement plants, shipyards, power plants, steel mills, sugar mills, etc., we manufacture perforated cable trays out of mild steel or CRC that are painted and installed according to site requirements.